Demonstrating the industrial relevance of hybrid nanoporous materials

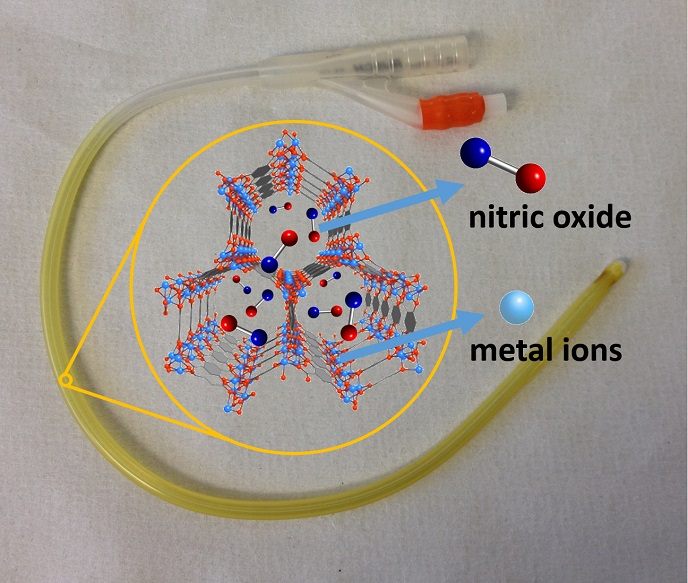

Over the past two decades, researchers have discovered several new classes of nanoporous materials (NPM), including aluminosilicates and metal-organic frameworks (MOF). Nanoporous materials can generally be defined as high surface area powders having pores in the nano-range. MOFs are a family of porous compounds consisting of metal ions or clusters coordinated with organic ligands to form one, two- or three-dimensional porous structures. Despite the significant potential this new class of materials offers, they have not yet found their way into industrial processes and applications. This is because the materials required to create them are currently seen as too expensive and not in a shape that justifies their industrial use. Thanks in part to the EU-funded ProDIA (Production, control and Demonstration of structured hybrid nanoporous materials for Industrial adsorption Applications) project, this is about to change. The project demonstrated the feasibility of large-volume industrial production processes for hybrid nanoporous materials as finished products. “In ProDIA, we developed processes for the production of nanoporous powders, including MOFs and aluminosilicates, using sustainable solvents like water or close-to-solvent-free processes,” says ProDIA project coordinator Richard Blom. “We also demonstrated the shaping of such materials at the same scale.” Demonstrating the sustainable production of NPMs The project’s consortium partners conducted four pilot-scale demonstrations: onboard adsorbed natural gas (ANG), removal of toxic industry chemicals (TIC), adsorption driven heat-pump applications (AHP) and antimicrobial agents to be used within healthcare. These pilots showed that by switching from state-of-the-art adsorption materials (typically silica and active carbon based) to new NPMs, industry can achieve significant improvements in energy and system size compared to existing technologies. From this work, ProDIA researchers succeeded in demonstrating that sustainable production of NPMs is possible at the >10 kg scale. They also produced shaped bodies of the chosen NPMs with negligible reduction in performance compared to precursor powders. According to Blom, the project has shown that it is possible to shape MOFs for specific applications, and that the shaped MOFs – at least for selected adsorption-based applications – have significant improvements in performance compared to the adsorbents commercially used today. “One of the main messages coming out of this project is that MOF-based adsorbents do not necessarily need to be expensive,” he says. “Another key takeaway is that shaping MOFs is possible, but one needs to take into consideration the fragile nature of these materials, which limits the use of high pressure and temperatures during the shaping process.” Dare to take the leap The project’s results have already received attention from a number of industries. Several of the SMEs and larger enterprises involved in the project are set to adopt the ProDIA processes to further develop their business. Furthermore, the project’s research-oriented partners continue to develop these processes in new research projects and potential spin-off companies. “I really hope the developers of adsorption-based technologies and material manufacturers will soon dare to take the leap into the world of MOF – optimising their instrumentation for this new family of adsorbents,” adds Blom. “Considering the possibilities that the huge chemical diversity of MOFs offers, I am sure making this switch will pay off in the long-run.”

Keywords

ProDIA, nanoporous materials (NPM), aluminosilicates, metal-organic frameworks (MOF), nanotechnology