High-resolution sensor network to monitor turbine blade performance

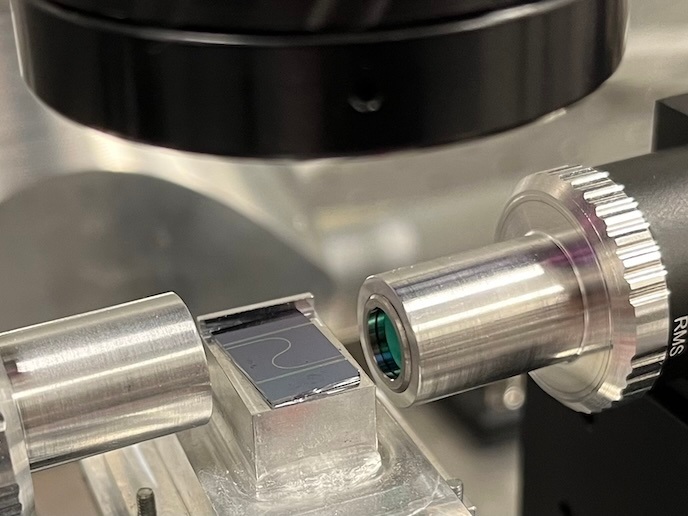

Turbines are large machines that produce power through high-speed rotation of blades via water, gas, steam or other fluids. They are used in aircraft engines, and steam and gas engines for power generation and other industrial turbomachinery. In the final stage of development, measurement of blade tip timing provides important information valuable to fatigue lifetime prediction, vibration analyses, reliability and safety assessments. Resolution of vibration is on the scale of millimetres. The technique has been difficult to implement during operation for monitoring purposes. Industry's only options for in situ monitoring yield far less sensitive and accurate timing of blade tip arrival. The EU-funded project 'Blade tip timing measurement technique for turbine monitoring in working conditions' (BTTMON) made major advances in technology geared towards resolving these issues. Scientists developed and tested a prototype magneto-resistive sensor for blade tip timing measurement with four digital sensing heads and associated signal processing electronics. Simulation and processing software can be used to optimise sensor placement and to test various configurations of rotation and vibration. It generates pulse sequences produced by a virtual rotor rotating with a defined irregularity and having a given number of blades vibrating according to simple functions. Finally, the team produced a small, portable test bench that will be useful in testing and calibrating the sensor system when it is installed in real turbines. BTTMON has delivered a prototype sensor, software to facilitate optimisation of both the sensor system and its placement according to specific turbine characteristics, and a portable test bench for calibrating the system on site. The team has thus laid the groundwork for application of high-resolution blade tip timing measurement in operational turbines for the first time. Commercialisation will be welcomed by turbine producers and end users alike thanks to benefits related to costs, time and maintenance procedures.