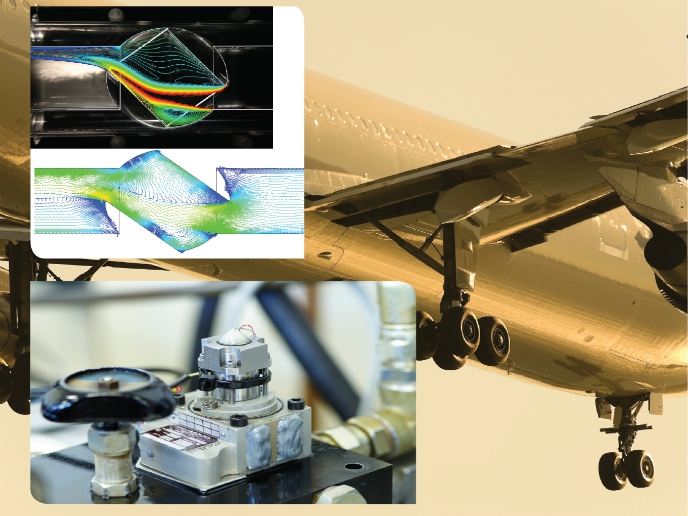

Wing de-icing technologies promise safer flying

Ice build-up on aircraft structures represents a flight hazard and has played a key role in several deadly accidents. It degrades performance and controllability and significantly increases pilot work load and aircraft fuel consumption. While in-flight de-icing technologies - such as the use of hot engine air - have been around for decades, researchers believe that aircraft safety and reduced energy consumption could still be further strengthened. ‘Some of these new technologies are close to commercialisation, which is now responsibility of the relevant partners,’ says JEDI ACE project coordinator Nadine Rehfeld from the Fraunhofer Institute in Germany. ‘Overall, though, this project really helped to highlight the need for further research and standardisation. For example, in the field of ice-phobic materials there is a great deal of interest in not only better understanding the icing process during flight, but also identifying relevant test regimes during different development phases. This is an ongoing activity, and will require international research and industry cooperation.’ Testing new technologies The JEDI ACE project focused on developing the next generation of integrated wing ice protection systems (WIPS). These include the use of new Shape Memory Materials (SMM) for aircraft de-icing applications, new anti-icing coatings and an ice sensor system for real time measurements of ice build-up on aircraft structures. Reliable testing methods for the performance of each developed component were also investigated. SMM are smart materials that respond to particular stimuli such as heat, changing shape and then recovering their original form. This change in surface characteristics can help aircraft wings adapt to icy conditions. ‘Future challenges for this approach are related to material availability as well as layer composition,’ explains Rehfeld. ‘Coating layers need to show excellent adherence.’ Different coating approaches were also developed, including super-hydrophobic coatings for areas behind the leading edge of wings. By comparing results of different ice adhesion tests, the team was able to provide a ranking of coatings and identify which ones have most potential to support heating devices. ‘There are indications that test results correlate with different ice formation processes,’ says Rehfeld. ‘This requires further assessment in order to improve the reliability of test results and correlations with realistic icing scenarios.’ Novel photonic sensors for real-time ice monitoring were also developed and a prototype embedded in an aerodynamic surface. Benefits of international cooperation By bringing together European and Japanese researchers (the project received funding from both the EU and the Japanese Ministry of Economy and Trade), JEDI ACE benefited from having a uniquely global perspective on the issue of aircraft safety. ‘This project proved to be a great opportunity for all participating research partners to learn from each other and to bring in experiences from different continents,’ says Rehfeld. ‘This applies not only to icing test facilities and coating development strategies, but also to de-icing technologies and ice sensing devices.’ Next steps, says Rehfeld, will involve establishing the reliability of components, developing up-scaling processes for materials and defining new manufacturing and processing rules. She also envisages further collaboration in order to fully integrate all concepts at the aircraft level. ‘This means interdisciplinary working groups consisting of coating suppliers, sensory specialists and aircraft manufacturers. Certification bodies also need to be included.’ Another exciting possibility for the future is transferring JEDI ACE results to other sectors such as wind energy, rail and automotive applications. ‘The interest in materials we have developed has been very high,’ says Rehfeld. ‘We’re busy looking at ways of how to implement these results across a range of products.