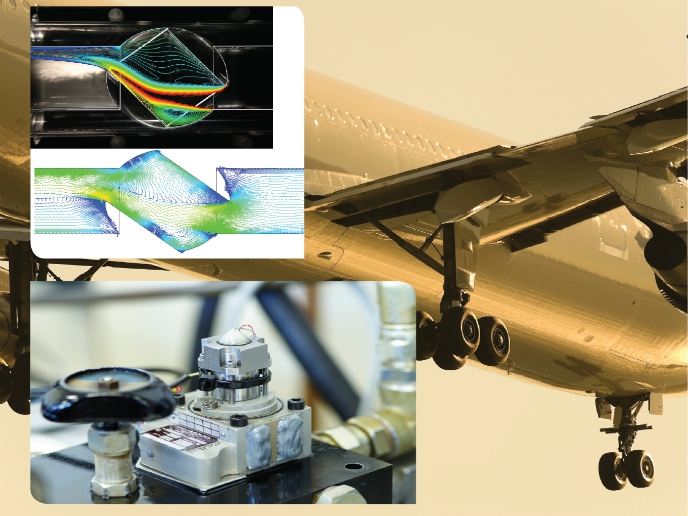

A step forward in ice simulation

As icing conditions pose one of the greatest risk to aircraft engines – and to the safety of air travel – the certification process for even the most high-tech aircraft engines is demanding, to say the least. Before a new engine is used to power a jet from Point A to Point B, it must first satisfy a rigorous certification process. Part of this multi-layered process involves being certified for use in icing conditions and, because the icing phenomena is so complex, certification tests are never simple. The main challenge is that, when it comes to icing and its effect on aircraft engines, engineers have access to a very low level of prediction capability. As a result they must rely on a very fragmented knowledge based on past empirical evidence. With the development of the next generation of engines, there is a crucial need for a way to better predict these icing aspects early in the design process and, based on this information, develop state-of-the-art ice protection systems. Thanks to new simulation methodologies developed by the EU-funded STORM project, it is now possible for engineers to more easily predict these icing aspects. Specifically, the simulation solution is capable of making accurate predictions as to ice release, ice accretion with runback aspects and ice trajectory. Based on this improved knowledge of engine component behaviour under icing conditions, the project has laid the foundation for the development of several innovative technologies for ice protection. ‘The STORM research has contributed greatly to improving cost efficiency for future engines and in developing a higher level of competitiveness in the field of ice protection systems,’ says project coordinator Morgan Balland. Building a knowledge base For each of the three main focus areas – ice release, ice accretion and ice trajectory – researchers gathered, analysed and consolidated all available information, thus creating a comprehensive knowledge centre from which simulation tests, designs and technological development could be based on. For example, based on a thorough literature review, STORM researchers identified different ways of measuring ice adhesion. ‘Here we were able to introduce a standardised approach for measuring ice release based on a selection of reference materials and test conditions,’ explains Balland. During the project’s testing of ice block trajectory, researchers identified five ice shapes representative of typical shapes of accretion for engine and aircraft application. ‘Having this knowledge at the start of the design process allows engineers to design aircraft engines capable of withstanding each of these ice shapes, as opposed to basing their designs on best guesses,’ says Balland. New technologies This research also laid the foundation for the development of several new technologies aimed at mitigating icing risks. For example, as to coating technology, researchers developed a score card using different application requirements. ‘In parallel to this, we also created a list of the most promising coatings based on previous research projects and partner recommendations,’ adds Balland. For Active Ice Protection System technologies, the project identified three potential solutions and successfully carried out testing of their engine and nacelle components. A big impact Thanks to the project’s research, aircraft engine designers now have access to an extensive database on ice mechanical properties – all compiled into a validated simulation and European standard procedure for ice release tests. This includes detailed models of ice release phenomenon and best practices, among other essential information. ‘With this information in hand, we will see a reduction of the conceptual design phase for retrofitted engines and new engine architectures, along with a reduction in the lead time and costs for testing these designs,’ concludes Balland. ‘Most importantly, this will result in safer aircraft engines and safer air travel.’