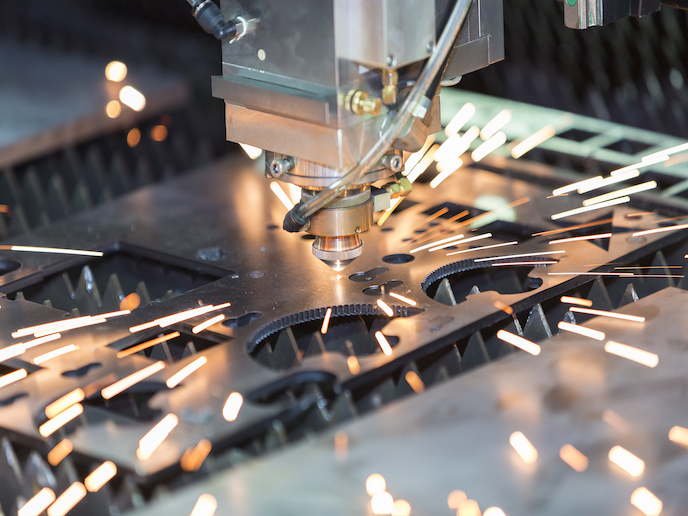

Prototype developed to monitor the temperature of metal cutting tools

A challenge with the metal cutting tools used in manufacturing is the heat they generate. The high temperatures travel throughout the body of the tool and can result in diminished cutting performance, reducing the quality of machined surfaces. This makes the accurate monitoring of tool temperature during machining vital. While the temperature of tools can be estimated from the colour of fillings and shavings known as chips(opens in new window), monitoring temperature distribution accurately is problematic. Direct measurement using sensors is almost impossible because of the challenging environment, with high pressures and cutting fluids risking sensor damage. The solution developed by the EU-supported MoMenT(opens in new window) project was to create a combined cutting and monitoring tool, which incorporated carefully spaced sensors. “Our prototypes and algorithms allowed us to accurately gauge the temperature in the cutting zone based on the sensor readings,” explains Rachid M’Saoubi, R&D expert at Seco Tools(opens in new window), the project host, and supervisor of Marie Skłodowska-Curie Actions fellow(opens in new window) Vyacheslav Kryzhanivskyy.

Modules to monitor heat distribution

When temperatures and the thermophysical properties of tools are known, heat fluxes can be determined. To get around the problem of not being able to obtain readings from the cutting zone itself, MoMenT’s sensors measured temperatures at several points beneath the cutting insert. Algorithms then extrapolated from these readings to calculate the temperature for any point in the tool. A ‘Thermal Resistance’ module used a Light Flash Apparatus(opens in new window) (LFA) to collect information about the thermal resistance of the tool assemblies, alongside a modelling algorithm which calculates cutting temperature. This is complemented by a ‘Temperature Distribution’ module containing the MoMenT cutting tool prototypes equipped with thermocouple(opens in new window) and thermistor(opens in new window) sensors. This module also used modelling algorithms to calculate the heat distribution or flux. Finally, the ‘Coating Investigation’ and ‘Cooling Investigation’ modules quantified the effect of coatings on heat fluxes flowing to the tool and measured the coefficient of heat exchange, depending on the cooling strategy adopted. “Testing demonstrated that our system was able to narrow the range for effective machining strategies, helping industry to quantify the thermal effects of different tool coatings, materials and cooling strategies,” adds Kryzhanivskyy.

Towards industry 4.0

More efficient machine cutting technology offers increased productivity for manufacturers, alongside improved product quality for consumers. Tools carrying thermal sensors will be of particular interest for the automation of traditional manufacturing and industrial practices using modern smart technology or Industry 4.0(opens in new window). “A widely available tool with thermal sensors capable of online monitoring of the temperature in the cutting zone is a distant prospect. For now we are improving and further testing our prototype,” notes Kryzhanivskyy. The team have already integrated wireless signal transmission into their temperature sensors. The next step is to further integrate the system so that decisions about cutting conditions (speed, feed, depth) could be based on temperature distribution within the tool body in real time. This ongoing work is being undertaken in conjunction with the ToolSense project(opens in new window) (with VINNOVA(opens in new window) and the Eureka cluster funding)(opens in new window). It has been set up to develop, upscale and commercialise sensors for online measurement and monitoring of forces, vibrations and temperatures in machining processes.