Supercomputer simulations help sculpt new aircraft designs

Aviation is a fundamental part of today’s society. Growing concerns about the environmental impact of flying means the industry is working to optimise aircraft to make them quieter as well as lighter and more aerodynamic, reducing fuel use and carbon emissions. Aircraft design is an extremely complex task, requiring the integration of knowledge from multiple disciplines, including aerodynamics, structural design and acoustics. Crucially, investigating new designs often requires the use of expensive wind tunnels and test flights. There is a clear demand within the European aircraft industry for digital tools that can act as a virtual testing facility. The NextSim(opens in new window) project set out to increase current capabilities in computational fluid dynamics (CFD), a critical component of aeronautical design. It achieved this through the development and release of the numerical flow solver CODA (a tool for simulating the behaviour of fluids), which is tailored to run efficiently on Europe’s next generation of high-performance computing (HPC) machines. “By re-engineering current CFD tools and leveraging advanced parallel computing platforms, the project aimed to streamline the design process, reduce lead times and enhance the efficiency of virtual mock-ups,” explains Oriol Lehmkuhl, large-scale computational fluid dynamics group leader at the Barcelona Supercomputing Center(opens in new window) and NextSim project coordinator. “These efforts are aligned with the European Union’s goals for aviation sustainability and emissions reduction,” he says.

Next-gen simulations

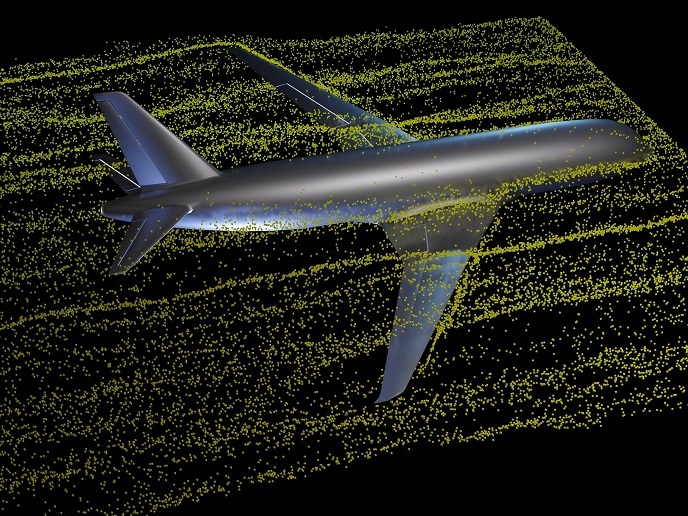

The project was organised around a suite of industrially relevant test cases, covering the aerodynamics of long-range aircraft in cruise flight and in conditions which require high lift (such as take-off and landing), as well as the exhaust flow of jet engines. These test cases drove the initial planning of the project. All tools and products from the project were also tested in these scenarios to demonstrate their potential. Simulations developed in the project include analysis of engine exhaust flow(opens in new window) for reducing contaminants and noise of aircraft, and the High-Lift Common Research Model(opens in new window), which reveals how air flows over the wings of aircraft during landing and take-off conditions. Thanks to NextSim, these can now be calculated faster and with significantly more accuracy.

Milestone advances

The project was carried out with support from the European High Performance Computing Joint Undertaking (EuroHPC JU)(opens in new window), an initiative set up to develop a world-class supercomputing ecosystem in Europe. “The outcomes achieved highlight the project’s remarkable impact on the aviation industry,” adds Lehmkuhl. “CODA now positions itself as a reference-solver for aerodynamic applications within the Airbus(opens in new window) group, with substantial implications for the aeronautical market,” he notes. “Additionally, the project has addressed market-relevant challenges defined by Airbus, demonstrating the feasibility of solving complex problems with high accuracy and computational efficiency.” The NextSim project also made significant strides in algorithm development, data management and optimisation for advanced HPC platforms. Best practices and guidelines have been shared with industry stakeholders to promote knowledge exchange and adoption of innovative solutions. Beyond the major advances made in CFD simulations, other achievements of NextSim include the enhancement of current numerical simulation tools for aeronautical design, expansion of HPC usage in the design loop of aeronautical products, improvements in CFD software efficiency, and overcoming existing deficiencies to significantly reduce certification costs by 2050 through virtual design and simulation. CODA will enter into production through the work of Airbus, DLR(opens in new window) and Onera(opens in new window) engineers at the end of 2024.