Developing human-robot collaboration for draping of composite parts

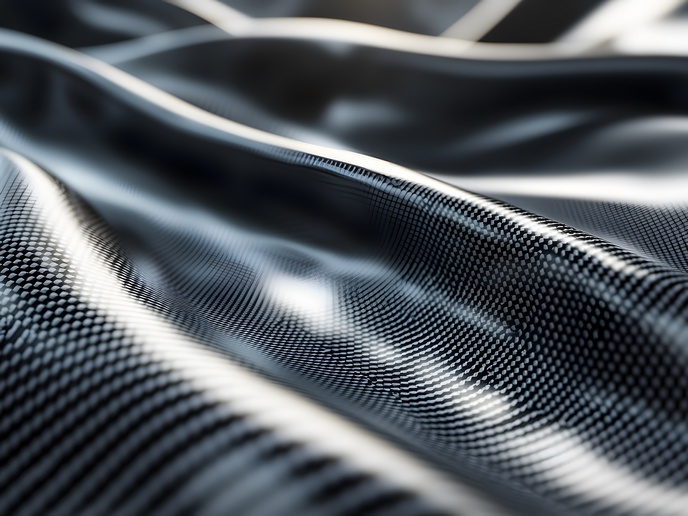

Draping is an industrial process through which carbon or glass fibre fabrics are overlain in layers and distorted to fit to the 3D shape of a mould. Draping is used for around a third of all carbon fibre parts and is widely used in automotive, aerospace, wind energy and sports industries. Roughly 4 000 companies in Europe use the technique. Yet making sure the draping is accurate in terms of the position and orientation of fibres, while avoiding wrinkles in the fabrics, is a difficult task. “The main challenge results from the fact that the carbon fabric is flat, while the part is a complex 3D shape,” explains Christian Eitzinger(opens in new window), head of the Machine Vision Department at PROFACTOR(opens in new window) in Austria. “Imagine wrapping a sphere in a piece of paper. This is impossible to do without creating wrinkles,” he adds. Carbon fibre fabric has the ability to adapt to such shapes by internally changing its angles. Yet, controlling how this angle changes is one of the main challenges of draping because it substantially impacts mechanical performance. In the EU-funded DrapeBot(opens in new window) project, researchers developed a new robot known as DrapeBot to assist humans in the draping process. The robot helps to transport large patches of material and drapes areas with lower curvature, while a human performs draping on the more difficult high-curvature areas. “There is good evidence that the technology has benefits,” says Eitzinger. “This now needs to be advertised by the project partners developing the technologies.”

Developing human-robot collaboration

DrapeBot is a robotic arm system complete with a large deformable gripper to transport and handle materials. It was designed with human-robot collaboration in mind, and comes with a range of components to assist with this, including sensors for quality control and to locate humans, and an AI-driven human perception technology to identify their actions. “All of these components were developed in parallel and integrated on three occasions in the project to check their performance in the particular application,” explains Eitzinger. “The results of these integrated tests were then used to identify any remaining problems and address them in the following phase of the project.” Due to the size of the robots, there was a risk that substantial damage might occur, including to the researcher collaborating with the robot. So the team also developed rules to deal with these situations. “Luckily, we never needed to make use of these rules – aside from a few scratches on one of the robots there was no damage,” he notes.

Improvements versus human-only draping

Extended tests were performed by setting up the robotic workcell in the facilities of end users, part of the project consortium along with industrial technology providers. Through the project, the researchers carried out a detailed assessment of the project results relative to human-only draping. This showed an improvement of up to 47 % in productivity, measured in terms of process costs.

Working towards new prototypes and scale

The team will now work on initial prototype implementations, including some of the technological elements developed in the project. “This is now in the hands of the end users of the project to define and to proceed with,” adds Eitzinger. “Based on such prototype implementation, a scale-up will be possible.”