Achieving lightweight and sustainable EV batteries

Battery-powered electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) are increasingly common on European roads. Consumers recognise the advantages EVs bring, including reduced greenhouse gas emissions, quieter engines and decreased reliance on fossil fuel. However, the sector still faces major adoption barriers, particularly concerning battery cost, autonomy, charging time and sustainability.

Faster battery charging, better performance

The EU-funded MARBEL(opens in new window) project sought to address these challenges by designing and testing lightweight, sustainable, high-performance next-generation battery packs, environmentally responsible and circular by design. “Reducing battery weight and optimising energy density means less energy needed, which means you can drive more kilometres,” explains Eduard Piqueras, MARBEL project coordinator from Eurecat Technology Centre(opens in new window) in Spain. “We also looked at boosting battery system performance through maintaining temperatures at optimal levels to minimise degradation. This enables faster battery charging and larger battery lifespan.”

Embedding circularity into battery design

Circularity(opens in new window) was integrated from the earliest stages of battery development. The MARBEL team adopted a modular design philosophy, which supports repairability, disassembly and reuse, key elements of a circular battery pack. Recycled content was prioritised wherever technically feasible, such as with a battery housing manufactured using 60 % recycled aluminium, while design efforts focused on second-life potential for multiple components.

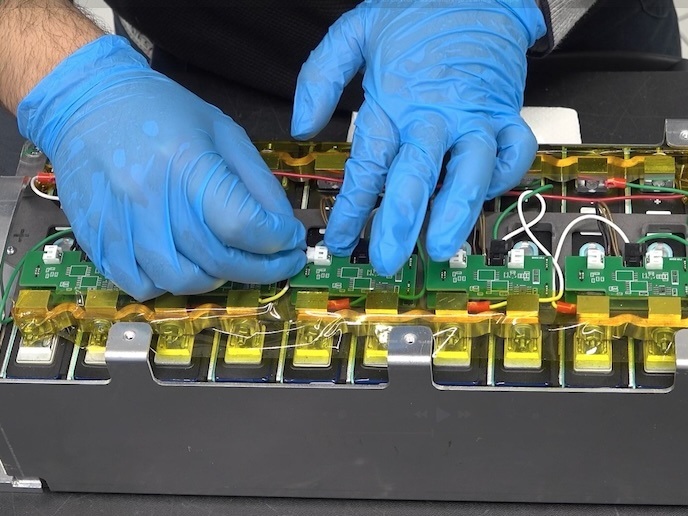

Smart battery management system

A battery management system (BMS) was built to act as the ‘brain’ of the battery. The BMS includes wireless communication and real-time smart energy monitoring, and each battery cell is able to communicate directly with the BMS via Bluetooth. Fewer wires also meant less cost, less weight and less complexity. A flexible battery test bench was built to assess the performance of MARBEL battery prototypes. This test bench was capable of communicating remotely with a motor test bench, meaning that tests could be run between labs at distance. Artificial intelligence was also used for data processing. The MARBEL battery prototypes were able to demonstrate progress in addressing the two key consumer concerns: limited vehicle autonomy and long charging times. In addition, important steps were taken to address maintenance complexity and overall costs, all while embedding sustainability principles throughout the entire life cycle.

Encouraging second-life applications

MARBEL also addressed end-of-life management and second-life applications. Strategies were implemented for the recovery of high-purity critical materials such as lithium, nickel, manganese, cobalt and graphite from end-of-life cells. This approach is essential to ensure compliance with the European Batteries Regulation(opens in new window). MARBEL also demonstrated how second-life applications can extend battery utility, with feasibility studies focused on electric motorcycles. The modular architecture facilitated disassembly and reconfiguration, enabling easy integration into alternative mobility solutions. This approach enhances resource efficiency and extends the functional life of components, reducing environmental impacts across the battery value chain. “Our goal from the beginning was to support EV adoption through batteries that are not only high performing, but also more circular and sustainable,” concludes Piqueras. “This is what future battery packs must look like: smart, efficient and sustainable by design.” Around 20 exploitable results in total were identified, and these will now be explored through future projects and collaboration with the COLLABAT(opens in new window) cluster. The know-how generated within the MARBEL project is the basis for new developments for more sustainable and circular battery packs.