How bio-based turf, furniture and panels are built to last

Cities want lower-impact products, but outdoor materials still have to survive sun, rain and heavy use. The EU-funded AMBIANCE project(opens in new window) focused on bio-based options that can be produced reliably and tested against everyday performance expectations. Across three demonstrators, the project combined material development, durability testing and digital manufacturing support; circular end-of-life routes were also considered from the start.

Three demonstrators for sport, public space and construction

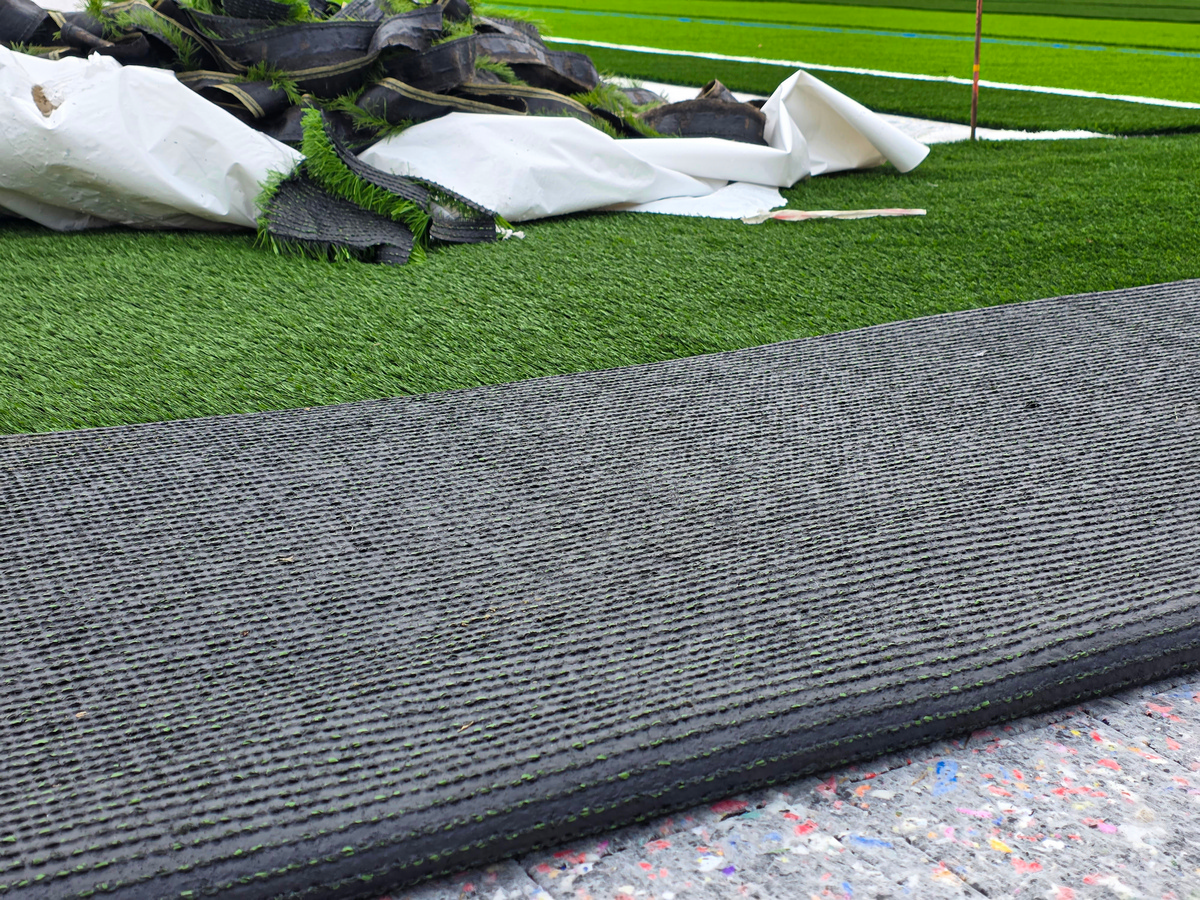

AMBIANCE chose products that people already encounter in daily life. Project coordinator Cristina Crespo says, “AMBIANCE is targeting three everyday ‘urban outdoor’ product families: artificial turf systems, 3D-printed outdoor furniture and decorative construction panels.” For sports facilities, the project focused on artificial turf pitches, improving the sustainability of filaments (yarns) and infills while meeting demanding performance requirements. For public spaces, it produced 3D-printed outdoor furniture through large-scale additive manufacturing. For construction, it developed decorative panels, including self-bonded biocomposite panels made from agricultural resources such as barley straw and reed canary grass.

Weathering tests for real outdoor stress

Outdoor ageing is a multi-stressor problem in which ultraviolet (UV) radiation, temperature cycles, moisture and mechanical wear can combine, leading to deformation, colour change, surface damage or loss of strength. Crespo highlights the most challenging part: “One could say that the hardest challenge is designing against combined UV and moisture effects while keeping materials circular and scalable for industrial production.” AMBIANCE used accelerated weathering and mechanical testing to screen materials and iterate formulations and processing. For outdoor furniture, accelerated weathering tests used controlled UV and moisture cycles with a strict pass criterion: samples had to remain undeformed and retain flexural strength within an acceptable reduction after prolonged exposure. For exterior construction panels, moisture resistance was critical and testing showed that applying a surface coating improved it. For artificial turf fibres, accelerated solar exposure tests were conducted under controlled conditions for accelerated weathering, assessing colour stability, mechanical integrity and potential degradation. In parallel, biodegradability tests in aqueous environments were conducted on infill materials to understand degradation pathways.

Circular end-of-life routes and a shopfloor digital twin

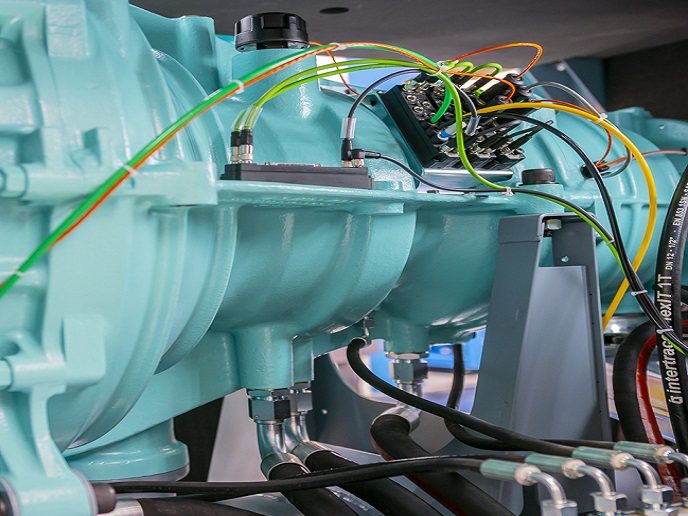

Circularity was applied differently across the three demonstrators because the materials and routes differ. Artificial turf systems were kept in thermoplastics as much as possible to enable mechanical recycling, while infill materials were evaluated for biodegradability. For 3D-printed furniture, recyclability was assessed even after artificial and natural ageing. For decorative panels made from agro-resources without added adhesives, chemo-mechanical recycling process was part of the intended end-of-life route. To help manufacturers maintain quality consistency, AMBIANCE built digital solutions that link production data to shopfloor decisions. Crespo explains, “AMBIANCE’s digital solutions are designed to turn production data into actionable decisions: selecting operating windows, detecting drift and supporting consistent quality.” This process involves cleaning and aligning sensor data, then using it in decision support systems with explainable AI so operators can see which variables drive quality. Data-driven models are combined with reduced-order models from high-fidelity simulations, letting teams test scenarios virtually before costly trials. Cost wins came from local feedstocks and material-efficient 3D printing, backed by supplier documentation and certification, where relevant, keeping durable and circular products scalable.