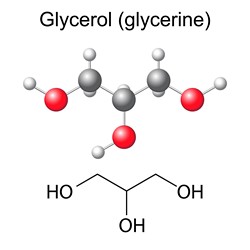

Glycerine product range gets expanded

Much of the world is now dedicating resources to finding alternative energy sources that reduce dependence on fossil fuels while reducing greenhouse gas (GHG) emissions. The market for biodiesel produced from oils and fats, which is environmentally friendly and made from renewable resources, is now booming. Furthermore, the co-product glycerine (also called glycerol) is widely used in pharmaceuticals and cosmetics. Biodiesel production is continually increasing and with it also glycerine production, saturating the glycerine market. One way to make use of biodiesel 'waste' is to turn co-products into useful substances. European scientists initiated the EU-funded PROPANERGY (Integrated bioconversion of glycerine into value-added products and biogas at pilot plant scale) project to develop technology that does just that. Researchers developed techniques that used the entire glycerine and methanol residue from biodiesel production. Added benefits were that the process supplied its own energy for product separation in the form of biogas and also yielded two value-added products – 1,3-propanediol (PDO) and fertiliser. PDO is an organic compound used to produce polymers for products such as adhesives, laminates and mouldings. Intensive research and development led to novel bioconversion concepts, a laboratory-scale mini plant, and construction of a pilot plant for large-scale demonstration of selected processes. Significant process innovations were made such as unsterile fermentation with simple medium for more robust bioconversion and cost reduction, new strategy of pH control for cost reduction and simplified downstream processing. The project successfully demonstrated the cost-effective production of high value-added PDO using waste glycerine from biodiesel production. Furthermore, the requirements for a sustainable technology were met by using renewable energy sources, making it CO2 neutral. As a result of the decentralised location and the reduction of volume, transport costs were considerably reduced, which also had a beneficial impact on the CO2 balance. PROPANERGY is thus expected to make a significant contribution to realising cost-effective biodiesel plant operation that should minimise dependence on fossil fuels.