New laser process to improve glass structure

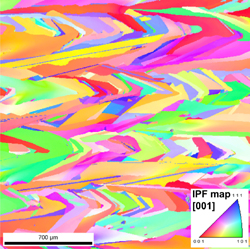

The EU-funded HIGH-EF project set out to provide the silicon thin-film photovoltaic (PV) industry with a unique process allowing for high solar cell efficiencies. Based on the combination of crystallisation and thickening by a solid phase crystallisation (SPC) process, laser SPC is a major breakthrough in silicon thin-film PV on glass since it greatly increases the grain size and reduces the density of defects and stress levels. Standard SPC processes on glass provide smaller grains with a high density of internal extended defects that hinder good solar cell efficiencies. It was deemed important, however, that the cost of industrial laser SPC implementation should not be more than the pure SPC process. The HIGH-EF project worked on developing low-cost laser processing using highly efficient laser diodes. The goal was to combine these to form a line focus allowing for the crystallisation of an entire module within a single scan. Attention was focused on identifying each competence needed for the project's success and to select partners to form a multidisciplinary consortium bringing together seven organisations from four Member States and one associated country. All efforts aimed to advance the technology of multicrystalline thin-film silicon solar-cells through the new laser SPC process.