Novel natural composites based on plant fibre

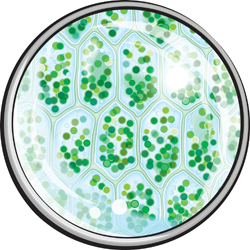

Nanocomposites typically consist of a polymeric matrix in which nanoparticles are embedded as fillers or reinforcements. Surface functionalisations achieved by embedding the nanoparticles at the matrix surface are much less common. However, much as cell surface receptors impart a wealth of functions to a living cell, such modifications on the surface of other materials can play an important role in the way the composites interact with other materials and substances. Scientists initiated the EU-funded project 'Surface functionalisation of cellulose matrices using cellulose embedded nano-particles' (SURFUNCELL) to develop novel natural nanocomposites with special properties on their surfaces. The matrix is made up of the main component of plant cell walls, cellulose (a complex sugar or polysaccharide), and the surface modifications consist of embedded nanoparticles stabilised by other polysaccharides. Importantly, the production process requires little modification of standard procedures and the nanoparticles are adsorbed and fixated using green synthetic methods. SURFUNCELL has published 20 scientific papers in peer-reviewed journals and presented its work more than 80 times at scientific conferences. Results have covered the entire process from preparation of the polysaccharides and nanoparticles through to the production of shaped cellulose devices. Researchers applied the technology in several demonstrators. Cellulosic yarns with antimicrobial properties were produced for use in textiles for hospitals, sportswear and the home. Partners have created two demonstrators applying the composites to filter membranes, hollow cellulose-based fibres that resist fouling and remove dangerous endocrine disruptors in drinking water. Another demonstrator highlights the use of the surface-modified cellulose composites as barrier films, resulting in biobased food packaging material with improved barrier properties. Finally, partners established a large lab-scale production line to produce paper with increased UV protection using less energy and fewer potentially harmful chemicals. With broad dissemination, SURFUNCELL scientists have delivered a complete technology platform based on natural materials and simple, scalable green production processes that will foster additional new composite discoveries. Demonstrators are in various stages of industrialisation and stand to inspire others to develop a continually expanding list of applications.