Seeing through circuit board counterfeit deception

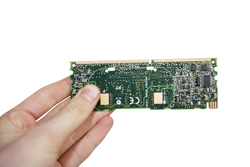

Electronics manufacturers that inadvertently use components whose performance or materials are misrepresented can face lower yields, device failures and product recalls. Inferior counterfeits can even cause malfunctions of safety-critical devices that lead to loss of life or environmental disaster. It is currently not possible to check each piece individually. Surface-mount components are packaged in reels or tubes of 1 000 to 20 000 pieces for automated feed. Removal from the original package followed by visual inspection and in-circuit testing is too costly and time intensive. Despite heightened precautions regarding the sourcing of safety-critical components, counterfeits have entered the supply chain in both the aerospace and defence industries. The innovative EU-funded CHIPCHECK project set out to deliver a low-cost X-ray inspection system to evaluate each individual component and significantly reduce the introduction of counterfeit printed circuit board (PCB) components in electronic products. Scientists employed a unique design based on lower-cost digital radiography (DR) X-ray modules used in industrial non-destructive testing and the medical and dental fields. Digital systems are more efficient than those using radiographic film, reducing exposure time for faster inspection. In addition, DR can be done in enclosed lead shield cabinets, thus reducing operator exposure. The prototype employs a remote X-ray controller housed in a metal enclosure. A mini X-ray detector was adapted from the dentistry sector to image small areas with very high resolution. An X-ray cabinet houses and integrates all parts to shield the operator from radiation. The CHIPCHECK system is capable of inspecting individual components on tape reels and other types of automated feeding systems in less than one second. Increasing influx of counterfeit electronics components from countries with minimal cultural sensitivity to or legislation to protect intellectual property rights is increasing the probability of failure of safety-critical systems. CHIPCHECK will enable inexpensive and reliable detection of counterfeit PCB components to increase safety and enhance the competitiveness of EU electronics manufacturers. With potential to become an electronics safety standard, the inspection system could have important impact on the EU economy with sales expected at manufacturing sites around the globe.