Turning sandcastles into glass sculptures

We may look right through it, but it’s everywhere: glass has been used for artistic and functional purposes for centuries. In recent decades, however, plastics have increasingly replaced glass in industrial manufacturing. That is largely down to cost – but not the cost of the material itself: “Plastics are made of polymers, which are more expensive per kilogramme than either metal or glass. However, they are cheaper to produce because they are so easy to shape,” explains Bastian Rapp, CTO at Glassomer(opens in new window).

The best of both worlds

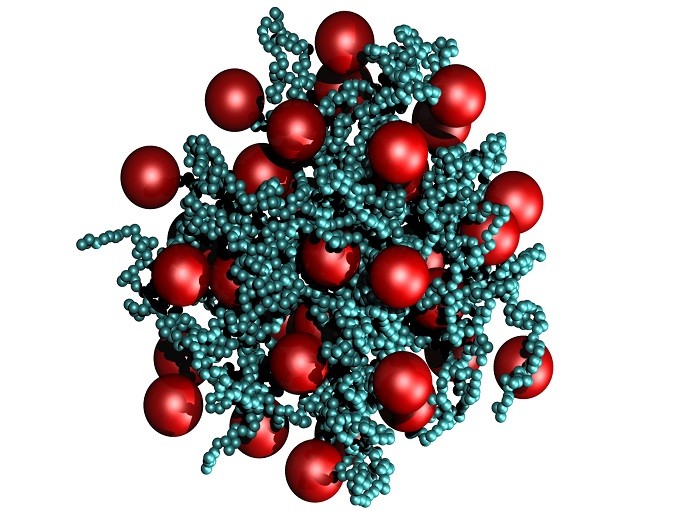

The company has developed a methodology for producing glass using polymer-shaping technologies. An EU-funded project has now enabled the Glassomer team to scale up the process for mass production. Traditional techniques to shape glass such as melting or grinding have a large environmental footprint. “Glass melting produces around 250 kg per tonne of glass produced. Grinding, on the other hand, is a very wasteful process because most of the glass is converted to sludge, which cannot be used for anything else,” Rapp says. The Glassomer process uses silica(opens in new window) nanoparticles, which can be thought of as a sand of tiny glass particles. These particles are available off the shelf and commonly used as thickening agents, for instance in toothpaste and lotions. The particles are mixed with a polymer that acts as a binder and given the desired shape using industrial processes such as 3D printing or injection moulding. The shaped object is then submerged in warm water to remove the plastic binder again. “It’s surprisingly mechanically stable, but it’s essentially a sandcastle,” Rapp notes. As a last step, the object is put into an oven where it densifies into a transparent piece of glass.

Less waste, less energy

Using a recyclable polymer as a binder enabled the team to make their technology greener than conventional procedures while also bringing production costs down. “Compared to glass melting, our process saves up to 70 % of energy,” Rapp remarks. “Glass melting involves a phase transition: you need a lot of energy to make it mouldable.” The Glassomer process uses sintering, which is less energy-intensive: “You bring two surfaces into close contact and increase the temperature just enough to make the atoms sufficiently mobile for them to diffuse across the interface; over time, that interface will disappear.” The source of heat is also a major driver of sustainability. “While the traditional glass-making industry uses natural gas, our oven infrastructure is completely electrical. If that electricity is generated renewably, you save massive amounts of CO2.”

High-purity glass

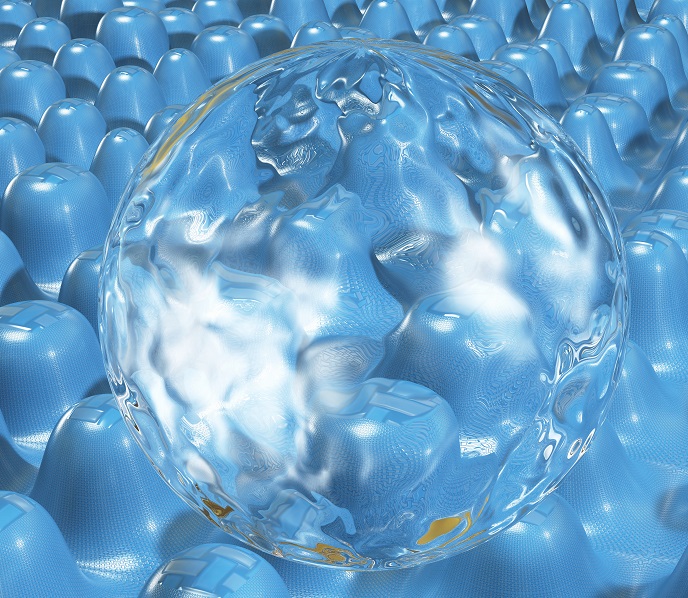

The result of this novel process is pure silica glass(opens in new window), a material with high value for many different areas thanks to its natural properties, such as transparency, heat resistance, chemical inertness and biocompatibility. Application areas include optics(opens in new window) (think smartphone camera lenses) and high-tech lab glassware(opens in new window), as well as artistic design(opens in new window) and glass used for packaging such as jars and bottles.

A million pieces a year

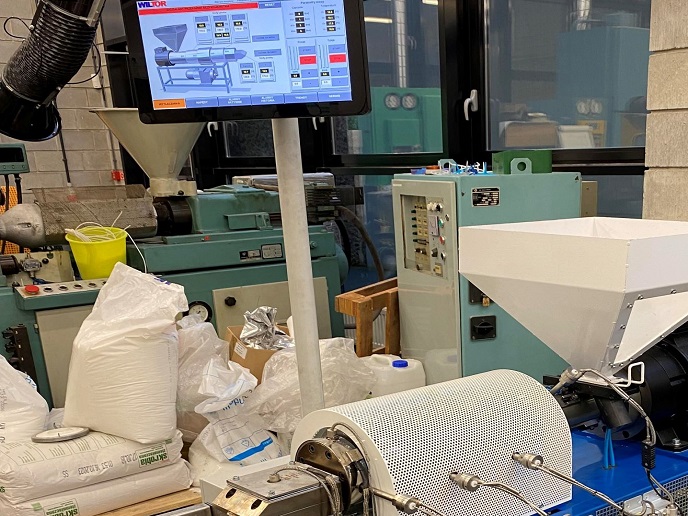

The EU funding has been instrumental in getting the injection-moulding process ready for industrial-scale production. Glassomer is already manufacturing and selling components at a smaller scale and is now looking to reach a million pieces a year. The team has deployed state-of-the-art injection-moulding machinery for mass production and is currently working to iron out any remaining issues to achieve complete reliability.