Novel coolants improve performance of EV batteries

Transportation is responsible for roughly 20 % of energy utilisation, and electric vehicles (EVs) have made significant inroads into the passenger vehicle market. Yet in the heavy-duty, marine and aviation sectors, which account for the majority of energy consumption in transportation, there has been very little EV penetration. Significant technological challenges must be met for EVs to advance in the transportation sector. Customers demand increased range, battery capacity and rapid charging. Improving the performance of battery thermal management systems (BTMS) will help deliver these improvements. The EU-funded I-BAT(opens in new window) project aims to increase the thermal performance of batteries by delivering innovations in cooling fluids, simulation frameworks and testing and measurement equipment that support rapid industrialisation of improved BTMS.

Battery thermal management systems

EVs rely on lithium-ion batteries, which have a thermal range of operation between 5℃ and 60℃. Maintaining this thermal range is critical, and BTMS typically use air, water or glycol to cool the battery. Coolants can operate on the battery through direct contact or indirectly, circulating around the cells in a jacket. I-BAT’s research concentrated on the flow and heat transfer capacity of the cooling liquid. The project also considered how the configuration of cells in the battery can optimise flow. Researchers have worked to design batteries with controlled flow vortices that maximise contact of the coolant across the battery’s surface structures.

Mineral oil-based coolants

Mineral oils have dielectric properties, meaning they do not conduct electric charge, but rather polarise it. This makes them suitable for use as battery coolants. I-BAT introduced additives to oil-based fluids to enhance the non-Newtonian characteristics of the coolant. The viscosity of non-Newtonian fluids varies under stress, and such manufactured viscoelastic properties facilitate the efficient flow of the liquid around the cells of an EV battery. The engineered coolants produced by I-BAT have great potential. As project coordinator Michael Wensing explains: “A new class of cooling liquids was created that meets battery system requirements and ensures especially stable flow, enabling robust and efficient immersion cooling.”

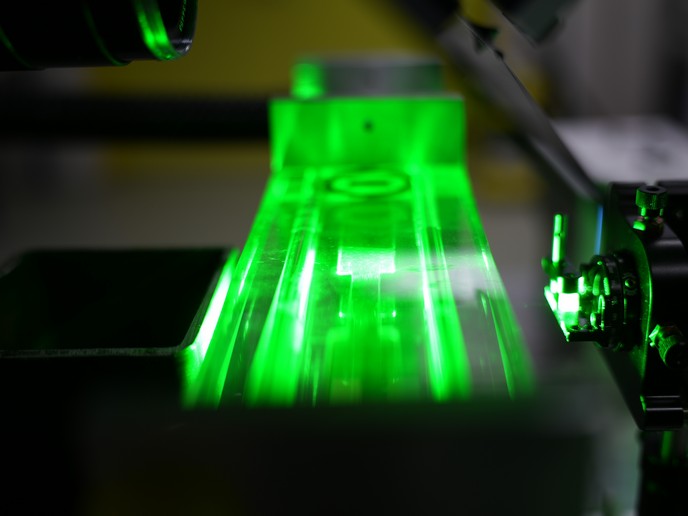

Simulation frameworks and atomic-layer thermopile sensors

Key to the uptake of the project’s solution is the capacity to test BTMS innovations. I-BAT developed a multi-scale simulation framework that includes molecular dynamics, meso-scale modeling(opens in new window) and computational fluid dynamics. Additionally, I-BAT developed atomic-layer thermopile sensors that use ultra-thin sensors to provide high-resolution data on heat flux. “The technology’s promise has already led to the founding of the start-up Hudyne(opens in new window) and, in our view, holds exceptional market potential for both products and related services,” Wensing notes. Industrial validation will accelerate market uptake of the project’s solutions. Putting complex fluid analysis tools and high throughput testing equipment in the hands of researchers and developers will aid this process. As Wensing shares: “Specialised testing equipment is vital for industrialisation, enabling calibration of simulations and evaluation of fluid properties and design performance.” Developments from the project are also being continued in Fiona Systems(opens in new window), a start-up in this field. Batteries must clear several technological hurdles if EVs are to achieve their potential in building a carbon-free future. By focusing on BTMS, I-BAT has developed a solution that increased the thermal performance of batteries.