Rotor technology for cleaner, greener and more efficient rotorcraft

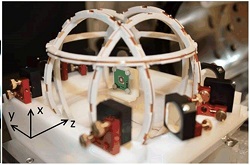

Gurney flaps are small tabs extending typically at right angles from the trailing edge of a wing or rotor blade. They can reduce transition to turbulence with important impact on both energy efficiency and safety. Effects of active gurney flaps have recently been investigated numerically but never been experimentally tested on a rotor. With this in mind, the EU-funded GUM (Active gurney on main rotor blades) project set out to measure the performance of a helicopter main-rotor model with an active gurney flap (AGF) integrated in each blade. Work began by defining, developing and validating a novel non-invasive measurement technique to determine the pressure field and minimise interference of test equipment and procedures. This information is used to calculate the pressure distribution around the blade. The method relies on particle image velocimetry (PIV) to measure the velocity field. Results show a considerable improvement in the state of the art of such methodologies. Project partners then turned their attention to two rotor test campaigns. A new PIV test rig was specifically designed and set up for such testing. For the first trial, they designed, produced and tested a set of passive blades on the whirl tower of a large wind tunnel in Milan. The blades were tested to assess the effectiveness of different size passive gurney flaps and to check and adjust the PIV setup waiting for the active blade set. The second campaign involved tests on active blades equipped with an AGF system. This helped to gather a large amount of information about the effects of different gurney flap actuation laws on blade performance. GUM brought to light the benefits of AGFs in increasing rotorcraft energy efficiency and reducing vibration. The post-processing tool to extract pressure from non-invasive velocity measurement should have widespread applications in fields related to fluid dynamics.