A multi-product microalgae biorefinery for food, feed and fragrance

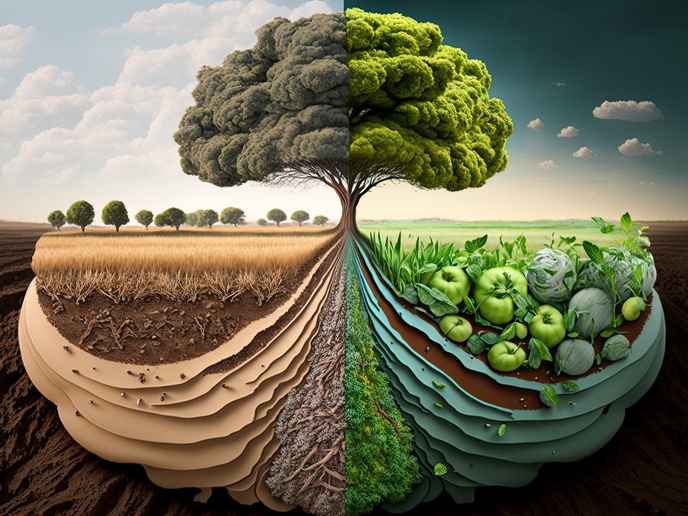

Our current agricultural and manufacturing systems come with negative environmental and ecological impacts such as pollution, habitat destruction and emissions from fossil fuel burning. To meet the goals of the European Green Deal(opens in new window) and limit these impacts, new processes need to be found. Algae present an environmentally friendly solution, with a wide range of potential uses as a fuel, food source and material for manufacturing. However, microalgae products currently struggle to achieve the same economies of scale as conventional products, making them currently underexploited as a crop. In the MULTI-STR3AM(opens in new window) project, researchers are developing a biorefinery for microalgae products, integrating several technologies to bring down costs of production and boosting scale and sustainability. The project received funding from the Circular Bio-based Europe Joint Undertaking(opens in new window), a public-private partnership. “To scale up and lower the costs of microalgae production, the MULTI-STR3AM project aims to demonstrate the integration of different technologies within a centralised biorefinery, in a production model that is both sustainable and economically viable,” says Mariana Doria, innovation manager at A4F-Algafuel(opens in new window) in Portugal and MULTI-STR3AM project coordinator.

Developing new microalgae products

The MULTI-STR3AM project is currently processing 10 different microalgae strains to produce 27 ‘biorefinery fractions’, or ingredients. In this project, A4F produces microalgae autotrophically(opens in new window) (using photosynthesis), while Phycom(opens in new window) is scaling up production by fermentation(opens in new window). Industry partners Upfield(opens in new window), ForFarmers(opens in new window) and IFF(opens in new window) are testing and evaluating these fractions to find the best candidates for pilot and demo scales, and in vivo trials. They will then be integrated into formulations of edible spreads, animal feed ingredients for poultry, pigs and ruminants, and other organic compounds for use in the fragrance industry. “Microalgae have a vast biosynthetic potential and are a rich source of lipids, protein and high-value compounds such as pigments,” notes Doria.

Creating a microalgae biorefinery

To create these products, the team successfully achieved a scaling up of microalgae production from 1 m3 to almost 100 m3. This led to a biorefinery with a capacity to process 10 tonnes of biomass per year. “This biorefinery was designed to process multiple microalgae species using different technologies and providing different products,” adds Doria. “The construction of the MULTI-STR3AM biorefinery involved the retrofitting of an abandoned industrial site, revitalising old installations into a sustainable biorefinery for the future.” The MULTI-STR3AM biorefinery was designed to use diverse species of microalgae for the generation of several high-value ingredients. By using different biomass feedstocks and integrating industrial waste streams provided by the production units, the biorefinery offers a zero-waste approach to operations.

Positive feedback

The project has already achieved several important results. This includes the integration of industrial side streams – such as nitrogen-rich effluent and industrial brine effluent – as feedstock for microalgae cultivation. The biorefinery has produced 26 microalgal samples for testing in food, feed and fragrance applications, from Spirulina, Dunaliella, Nannochloropsis and Chlorella. Some products are already being tested by end users, whose feedback is informing the ongoing development of the biorefinery. During the final year of the project, which ends April 2025, partners will expand their trials, scale up their prototypes for further testing and evaluate the formulation of products. To boost microalgae productivity, optimise biorefining processes and support industrial partners, the project also involves IMIC(opens in new window), iBET(opens in new window) and LNEG(opens in new window). “As the biorefinery expands and more equipment is commissioned, process optimisation is an ongoing process to reach the best conditions for microalgae fractioning and purification and refining,” concludes Doria.