Clean hydrogen production inspired by plants

Hydrogen has the potential to revolutionise Europe’s energy matrix, provide clean power and reduce the continent’s dependence on fossil fuels. Yet more than 95 % of current production methods for hydrogen generate large amounts of greenhouse gases, meaning it is not yet clean. In the CLEANH2 project, which was funded by the European Research Council(opens in new window), researchers sought inspiration from photosynthesis in plants, to develop new, cleaner ways of generating hydrogen. The CLEANH2 team, led by Nicolas Boscher(opens in new window) at the Luxembourg Institute of Science and Technology, engineered a range of polymers that mimic the process of photosynthesis, splitting water to obtain clean hydrogen. “For over 3 billion years, nature has been implementing water splitting using sunlight,” explains Boscher, coordinator of the CLEANH2 project. “Photocatalytic water splitting, also known as artificial photosynthesis, uses light to split H2O molecules into H2 and O2,” he says.

Creating photosynthesising polymers

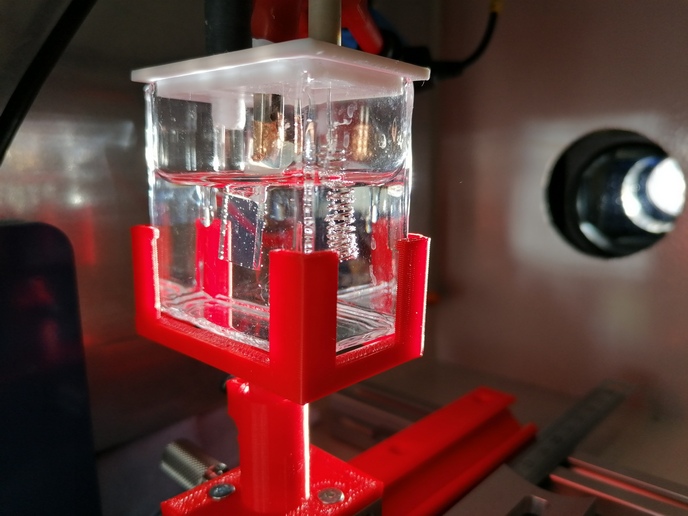

For their new generation of water-splitting polymers, the team turned to molecules known as metalloporphyrins, parent compounds to the photosynthesising chlorophyll found in plants. Metalloporphyrins are a good candidate for water splitting as they can easily convert between oxidation states to trigger electrochemical reactions and produce hydrogen. To create their new polymer photocatalysts, the researchers attached (polymerised) metalloporphyrins together. The resulting polymers are able to absorb light and convert it into energy, then allow electrochemical reactions to take place to create hydrogen. “The covalent conjugated bonding formed between the metalloporphyrins during their polymerisation ensures a cooperative effect between them, facilitating charge transfer and boosting the catalytic activity,” explains Boscher. Creating such polymers isn’t straightforward, however. The synthesis and practical use of metalloporphyrin-based polymers is limited by the fact that they don’t dissolve easily in liquids. So the team took a different approach, operating when the compounds are in a gaseous state. With the team’s new approach, they were able to successfully produce a range of new polymers, directly synthesised in thin film form. This means the researchers could easily investigate their ability to split water and produce hydrogen.

Exploring other catalytic processes

“Metalloporphyrinoids were selected by nature to fulfil numerous important catalytic reactions: photosynthesis by chlorophylls, respiration by cytochromes, vitamin B12 involved in metabolism,” notes Boscher. “The ability to precisely engineer the properties of metalloporphyrin-based polymer thin films such as achieved in the CLEANH2 project opens the way to address other important catalytic processes.” The researchers will now build on the results to engineer metalloporphyrin-based polymer catalysts to convert sunlight and simple feedstock molecules into fuel or advanced chemicals. They have already engineered and developed such catalysts for the high-yield and selective conversion of nitrates, found in numerous waste streams, into ammonia.

Revolutionising Europe’s ability to produce clean hydrogen

The plan is to synthesise even more advanced chemicals, work currently supported by Horizon funding in the SUN2CN project, which Boscher also coordinates. This project aims to deliver a standalone Solar-to-X device to convert simple, low-energy molecules found in waste streams into valuable carbon-nitrogen (C-N) chemicals, using sunlight as the only energy source. “C-N chemicals, such as urea and methylamine, critical for the agriculture and pharmaceutical industries, contribute significantly to human health and quality of life,” Boscher says. “If successful, the new device will eliminate the need for fossil resources and energy-intensive ammonia production,” Boscher adds. “SUN2CN aims to achieve a breakthrough in the chemical and energy sectors.”